Pneumatic Conveying

• Dilute-Dense-Semi Dense Phase, Controls and Testing.

Dilute Phase Theory

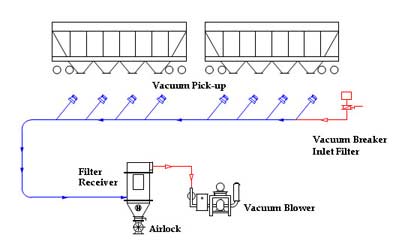

Dilute phase pneumatic conveying systems, also know as suspension flow, operate on the principle that the solids will be suspended in the conveying line air stream. This is accomplished by metering product into a moving air stream. Dilute phase conveying velocities typically are greater than 3500 FPM and material to air ratios are less than 12 to 1. Individual particles in the air stream will have some separation by their suspension in the air stream.

Dense phase conveying:

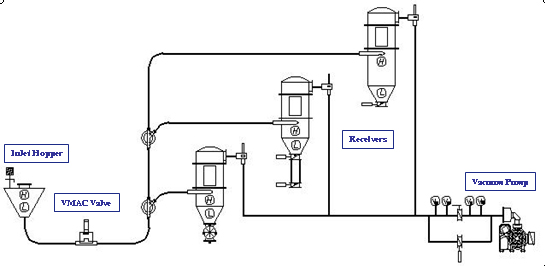

Dense phase pneumatic conveying systems operate below the minimum suspension velocity and are characterized by product moving along the bottom of the pipe in slugs or a moving bed. Product is conveyed below its saltation velocity at high differential pressures. Conveying velocities are typically less than 2600 FPM and material to air ratios of up to 100 to 1 are possible. Interaction of the particles in a dense phase system is greater than in dilute phase systems.